Need a technical advisor to answer your questions?

Detail

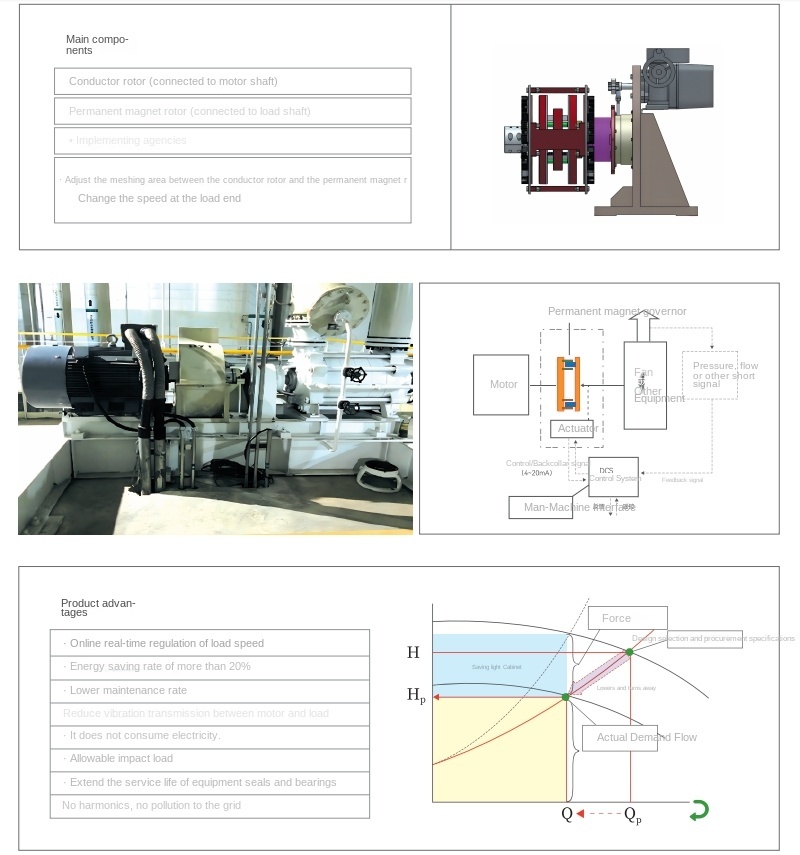

Chapter 1 Principle of Permanent Magnet Transmission

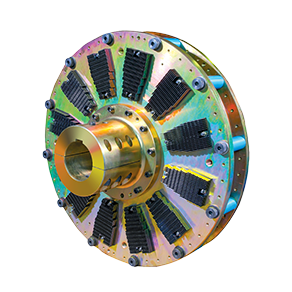

With the continuous progress of the production process of rare earth materials and the in-depth study of magnetic science, a new transmission technology-a permanent magnet drive was born. The permanent magnet drive has no physical connection but can transmit energy and adjust the size of the transmitted energy. It is known as a new revolution in the history of transmission.

Nanjing Diwa permanent magnet has many years of permanent magnet development and application technology, DYT permanent magnet drive products developed by MOSAIC company and has a number of world-leading technology, including fixed speed and speed control two categories each more than ten series. The product has the characteristics of high efficiency, energy saving, environmental protection and safety. It can replace hydraulic coupler and frequency converter and other products to realize soft start, torque limit and speed regulation, and provide guarantee for efficient and worry-free operation of your equipment.

Chapter Two DYT-B Series Standard Permanent Magnet Coupler

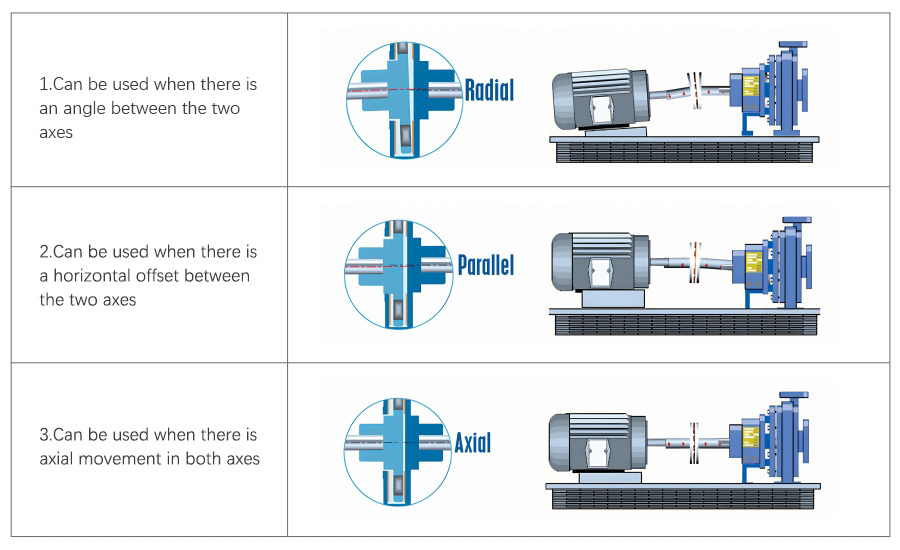

Solve Your Device Worries-Adopt Non-Connected Technology

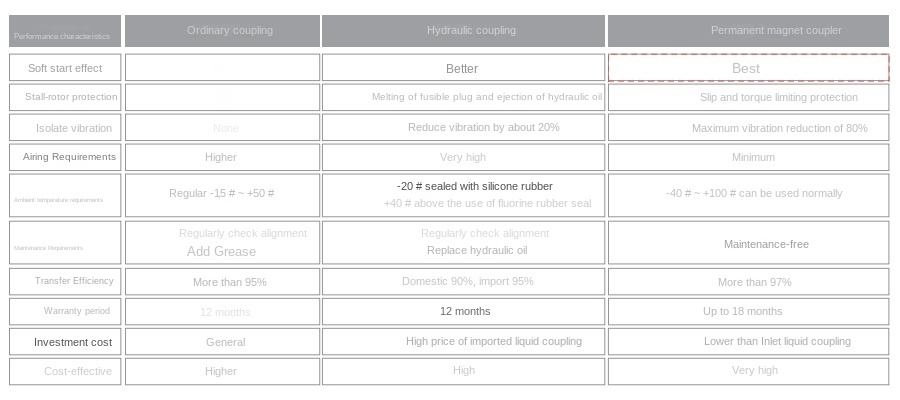

Comparison with ordinary coupling and hydraulic coupling

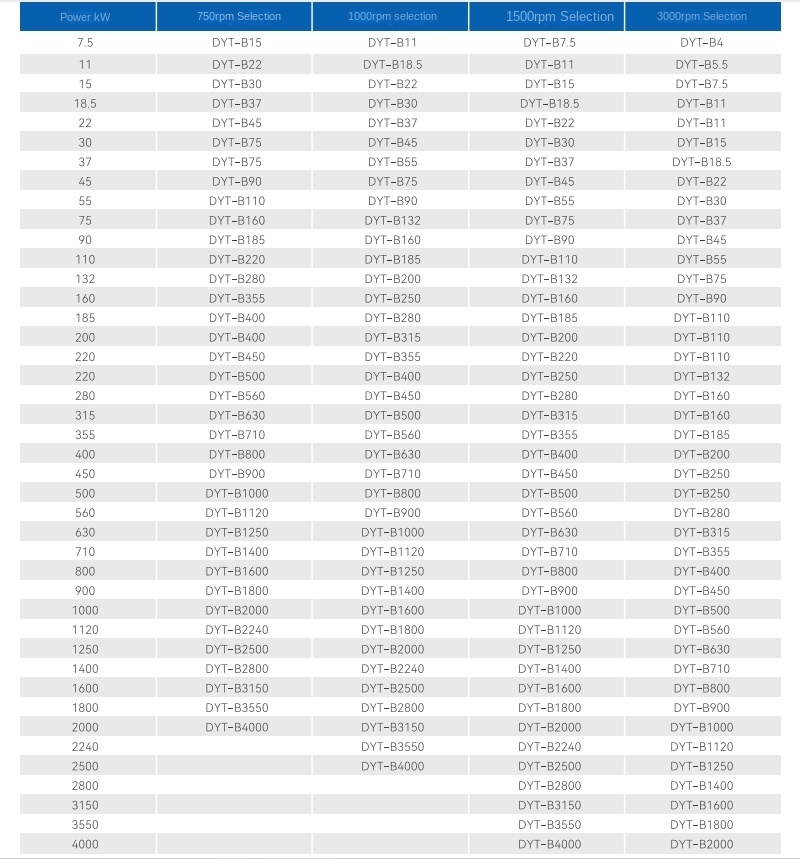

DYT-B series standard model

DYT-B Series Standard Permanent Magnet Coupler-Parameter Table

Please provide the technical parameters of the motor and load equipment: motor power, speed, load shaft power, installation size, ambient temperature and other data related to the working characteristics of the permanent magnet coupling, and the selection will be confirmed by the pre-sales technical engineer of Diwa permanent magnet;

DYT-X series limited torque type

DYT-X Series Limited Moment Permanent Magnet Coupler

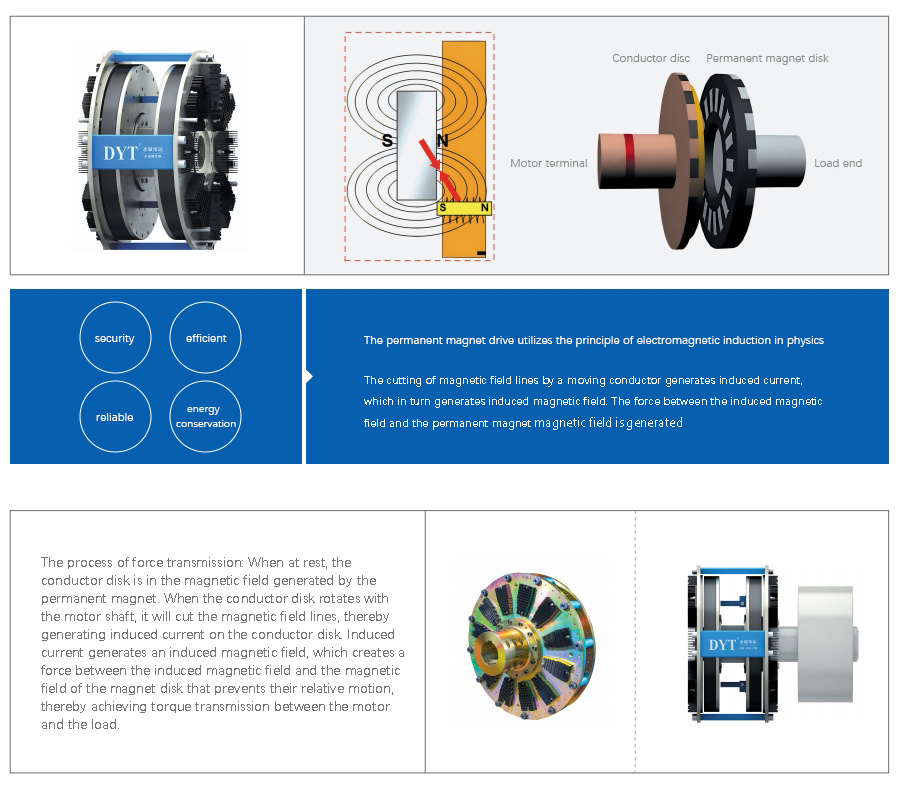

Principle

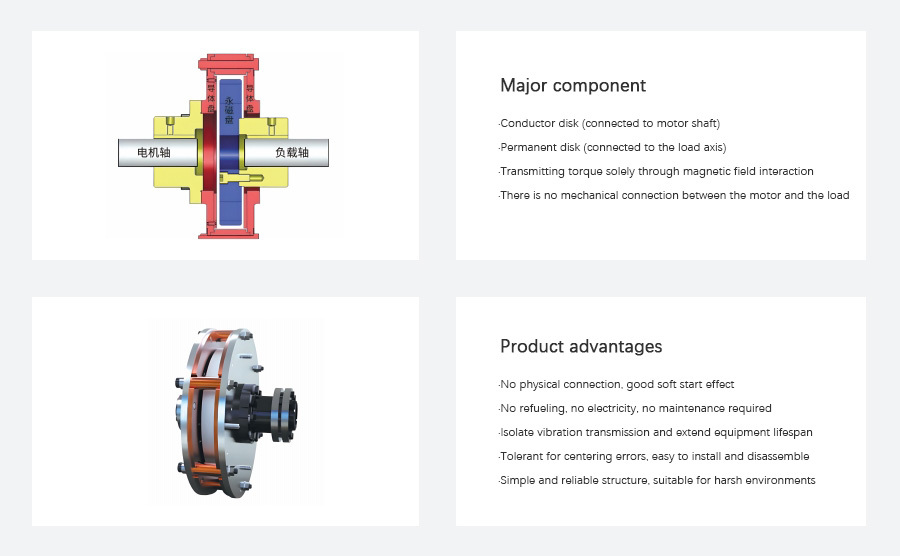

Using the principle of magnetic induction to transmit torque, it is composed of two independent parts, and the non-contact connection technology is used between the parts;

• A permanent magnet disc equipped with strong magnetism is mounted on the load shaft;

· The conductor plate equipped with copper ring is installed on the motor shaft;

The relative motion between the magnet disk and the conductor disk can generate eddy currents on the conductor disk and create a strong magnetic coupling force between the two. By adjusting the size of the air gap between the permanent magnet disc and the conductor disc, the required output torque is achieved. It can provide the highest transmission torque and the highest working efficiency. Due to the existence of the air gap, a large centering deviation between the motor shaft and the load shaft is allowed, and vibration can be isolated.

Features

With the characteristics of standard permanent magnet coupler, automatic reset after eliminating interference factors

Scope of application

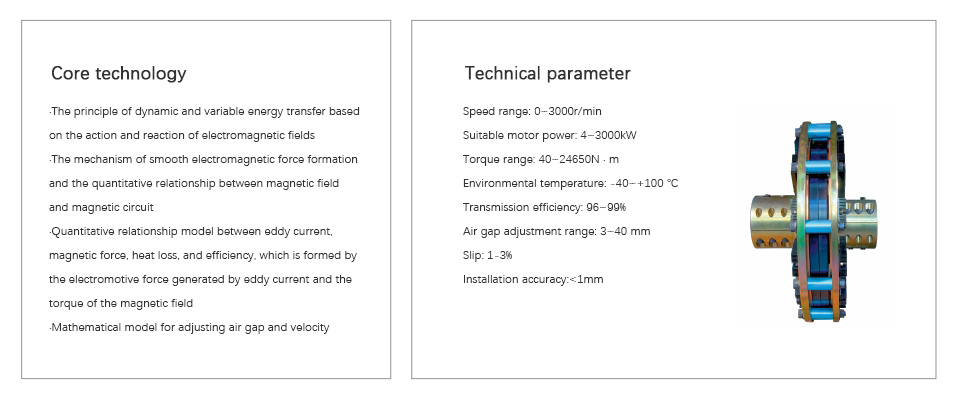

Motor: 4-4000kW

Speed: 0-3000r/min

Product Structure

Function and protection

· Limited moment type permanent magnet coupler can realize buffer start and overload protection function. When the equipment is just started, the rotating speed of the conductor disc is rapidly increased under the drive of the motor, and a strong repulsive force is generated between the conductor disc and the magnet disc due to the large rotating speed difference, thus pushing the magnet discs on both sides to move closer to the middle. At the same time, due to the relatively low rotating speed of the magnet disc, the torque limiter rocker arm is still in the horizontal position, preventing the magnet disc from moving closer to the middle and realizing delayed buffer start;

· As the speed of the magnet disc further increases, the speed difference between the conductor disc and the magnet disc gradually decreases, and the attractive force between the two is gradually greater than the repulsive force, separating the two, and the torque limiter rocker arm is under the action of centrifugal force Swing to the outside and keep it in a balanced position;

When the equipment has impact load or overload blocking, the rotating speed at the load end decreases sharply or even stops, and a huge repulsive force is generated between the conductor plate and the magnet plate to quickly push the torque limiter rocker arm to the middle of the magnet plate on both sides to the vertical position, so that the transmission is disengaged to realize the protection of the equipment. When the fault is eliminated, the speed of the load end gradually increases, and the equipment enters the normal working state again.

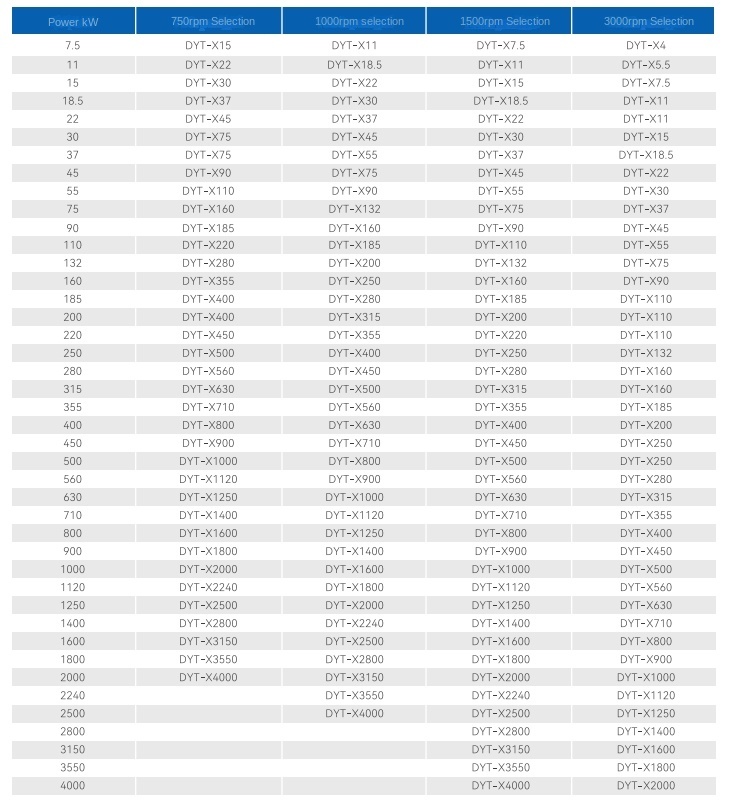

DYT-X Series Limited Moment Permanent Magnet Coupler-Parameter Table

* Please provide the technical parameters of the motor and load equipment: motor power, speed, load shaft power, installation size, ambient temperature and other data related to the working characteristics of the permanent magnet coupling, and the selection shall be confirmed by the pre-sales technical engineer of Diwa permanent magnet;

* The limited moment type not only has the function of delay type, but also can realize automatic reset after overload, which can replace the application of delay type;

DYT-T series speed regulating type

Chapter 4 DYT-T Series Speed Regulating Permanent Magnet Coupler

Product Message

Get in touch with our team in a timely manner and be happy You offer help

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible