Need a technical advisor to answer your questions?

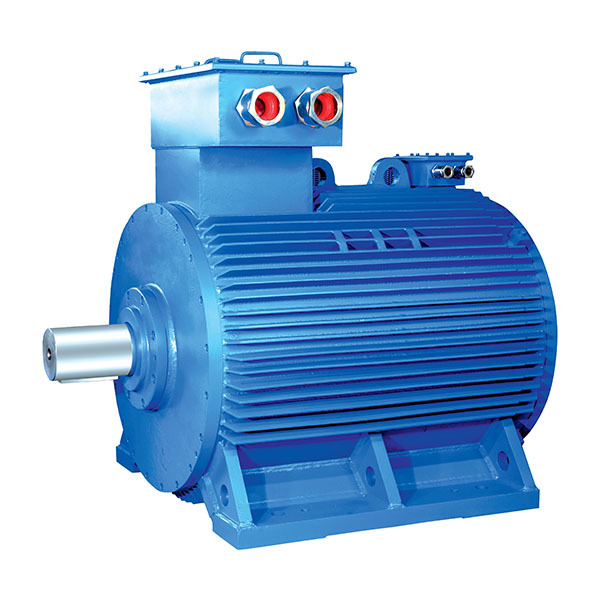

Permanent magnet low speed direct drive motor

Permanent magnet low speed direct drive motor

Detail

Chapter 1: Change and Innovation in Drive Systems

With the rapid development of industrial automation, new and higher requirements are put forward for different types of electric drive systems, including improving reliability, reducing power consumption, reducing maintenance costs and meeting the complex requirements of industrial processes.

With the development of magnetic material technology, power electronics technology, microcomputer technology and control theory, permanent magnet motor has been more and more widely used for its high torque-to-inertia ratio, high energy density and high efficiency. In particular, vector control technology and direct torque control technology as the core of the development of the servo control technology, so that a low-speed high torque revolutionary products-permanent magnet direct drive motor system came into being, it and the traditional drive system compared to remove the intermediate transmission over the bay link, to achieve the permanent magnet direct drive motor and the load side of the direct connection.

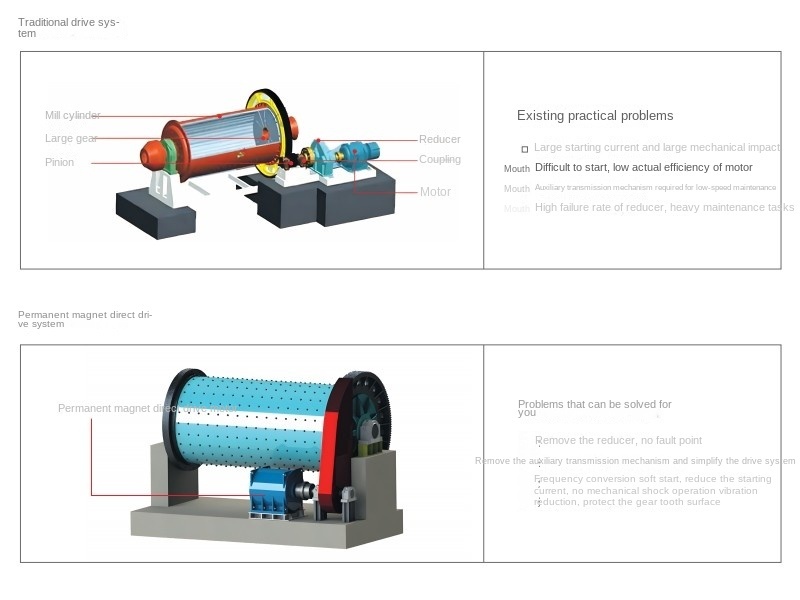

Application Advantages of DYT Permanent Magnet Direct Drive Motor System in Ball Mill

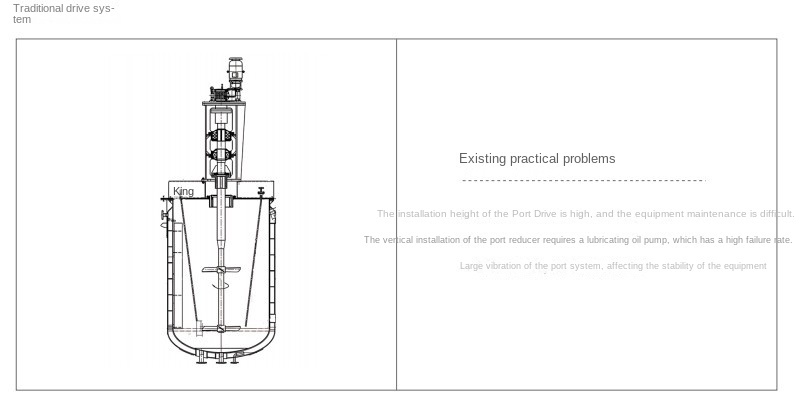

Application Advantages of DYT Permanent Magnet Direct Drive Motor System in Mixer

Core advantages:High efficiency and energy saving, large starting torque, strong overload capacity, variable frequency control soft start, direct drive load, truly maintenance-free

Chapter 2 Introduction of Permanent Magnet Direct Drive Motor System

The DYT permanent magnet synchronous direct drive system integrates variable frequency vector control technology, low-speed direct drive high-torque permanent magnet motor technology, intelligent control technology, etc., and uses "permanent magnet direct drive motor" to replace traditional mechanical drive devices to directly drive the load. The revolutionary removal of the reducer, wave coupler and other traditional equipment, so that the transmission system structure is simplified, the efficiency is improved, the noise is reduced, and the installation is convenient.

system composition

Core Technology

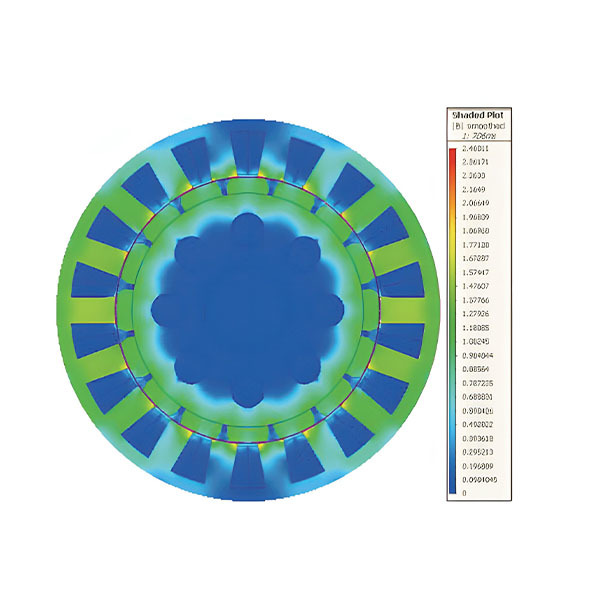

Professional finite element analysis techniques

Using advanced simulation software, through electromagnetic simulation and thermal simulation, the magnetic circuit design is continuously optimized, so that the system performance is optimal and the temperature rise is minimized.

direct torque control technology

Direct use of space voltage vector, directly in the stator coordinate system to calculate and control the motor torque and magnetic flux, the use of stator magnetic field orientation, with the help of discrete two-point adjustment to generate space vector directly to the inverter switching state of the best control, has obtained high dynamic performance of torque.

Anti-loss Technology of High-performance Permanent Magnet

The permanent magnet direct drive motor adopts the sintered NdFeB permanent magnet with the strongest magnetic force and the most stable magnetic performance, uses the finite element analysis method to calculate the local working points in the demagnetization state, obtains the actual working state, and effectively processes the permanent magnet to avoid its working point occurring on the demagnetization curve.

System process

system advantage

Stable and reliable, maintenance-free

The permanent magnet direct drive motor revolutionizes the original entire transmission system, removing the reducer and hydraulic coupler with very high failure rate in the original system, reducing the fault link points in the transmission system, and the motor directly drives the equipment load. The stability is greatly improved, not only reducing the vibration and noise of the original equipment, but also realizing maintenance-free in the later period.

High efficiency and energy saving

· Energy-saving principle one: less transmission link energy saving

Remove the traditional reducer, wave coupler and other transitional transmission links, reduce power transmission loss;

· Energy-saving principle two: direct drive motor high efficiency, low energy consumption

The efficiency of the permanent magnet direct drive motor reaches the international IE4 (higher than the national energy consumption standard);

Energy saving principle three: soft start energy saving, reduce the starting current

The direct drive motor adopts special frequency converter to control the start and operation, and the starting current does not exceed 2 times of the rated current, which reduces the impact on the power grid and the requirements for power supply capacity;

Energy saving principle four: power factor compensation energy saving

Direct drive motor power factor can reach 0.98, less reactive power loss;

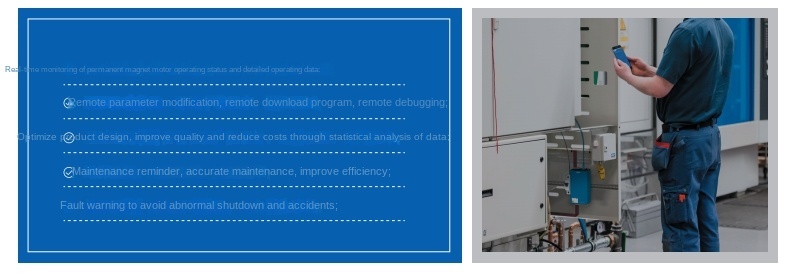

real-time condition monitoring

Large starting torque and strong overload capacity

Permanent magnet synchronous motor matching intelligent synchronous inverter-can constant output rated load torque of 2.2 times the starting torque; Completely solve the problem of heavy load start difficult, to avoid the asynchronous motor big horse-drawn car "phenomenon.

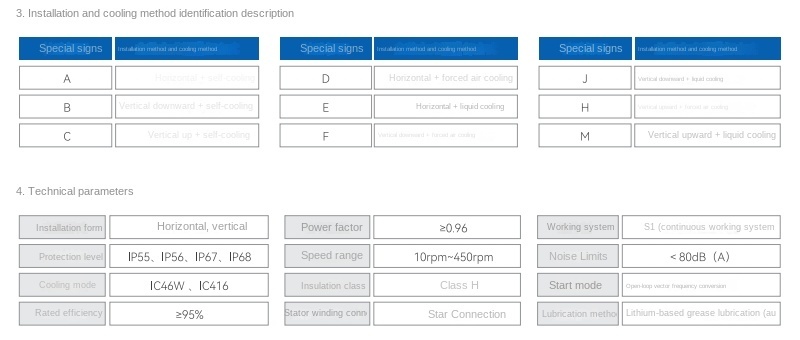

Chapter III Technical Parameters

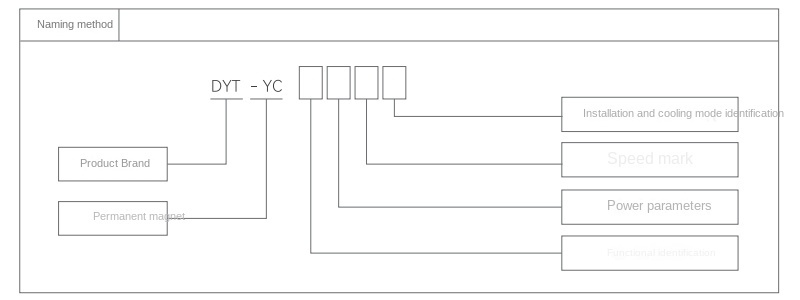

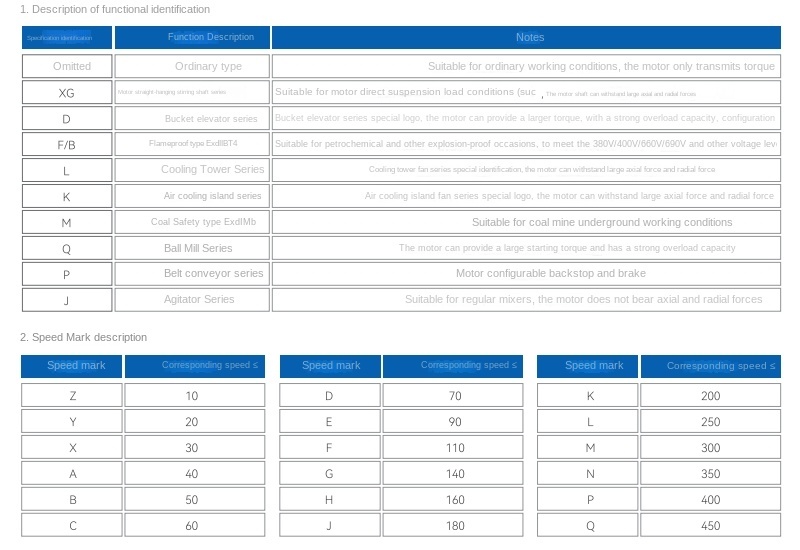

Description

Selection Description

The permanent magnet direct drive motor is a device directly connected to the load. The main reference parameter for selection is torque. The selection steps are as follows:

1. First, confirm the load shaft power and load speed;

2. According to the load shaft power and load speed, calculate the load torque: according to different load types, the torque needs to have a certain amount of surplus, and finally determine the torque of the permanent magnet direct drive motor;

3. According to different load types and load speed, select the motor speed closest to the working condition;

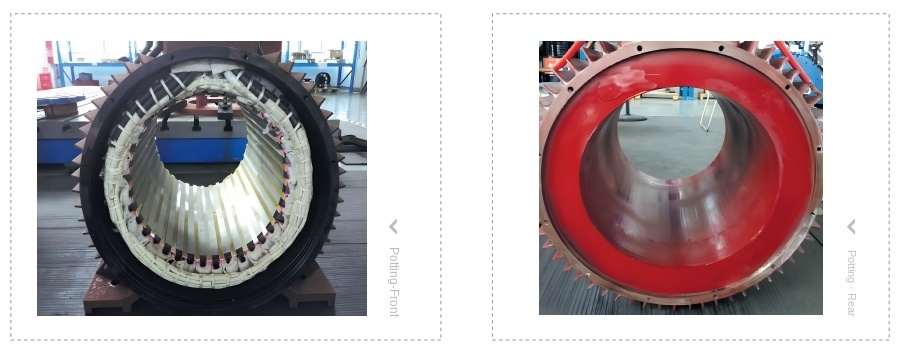

4. Cooling tower fan and air cooling island and other special conditions of the environment, the stator coil is recommended to use epoxy resin potting process;

The comparison chart before and after potting is as follows

Mixer

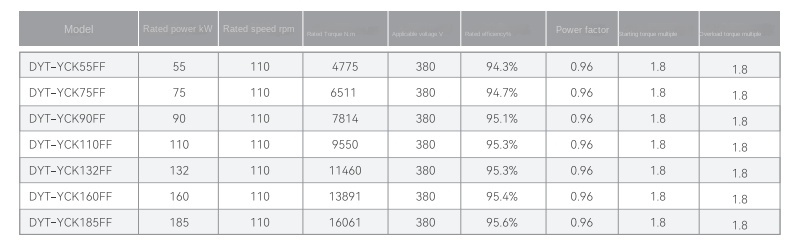

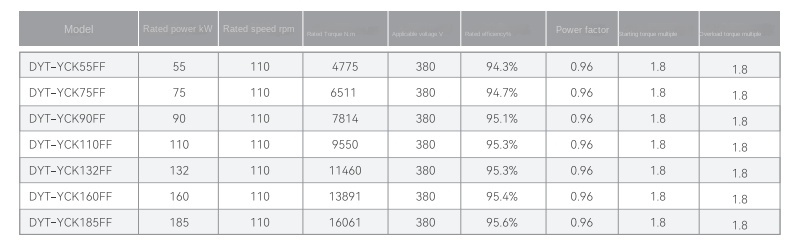

Permanent magnet synchronous direct drive motor for air cooling island-parameter table

Technical description: 1. Please consult Diwa permanent magnet technical department for the weight of the motor; 2. Please consult Diwa permanent magnet technical department for other speed conditions;

Mir cooling island

Permanent magnet synchronous direct drive motor for air cooling island-parameter table

Technical description: 1. Please consult Diwa permanent magnet technical department for the weight of the motor; 2. Please consult Diwa permanent magnet technical department for other speed conditions;

Cooling tower

Permanent magnet synchronous direct drive motor for cooling tower fan-parameter table

Technical description: 1. For other installation methods and working conditions, please contact Diwa Permanent Magnet Technology Department; 2. For other speed conditions and other voltage conditions, please contact Diwa Permanent Magnet Technology Department;

Ball mill

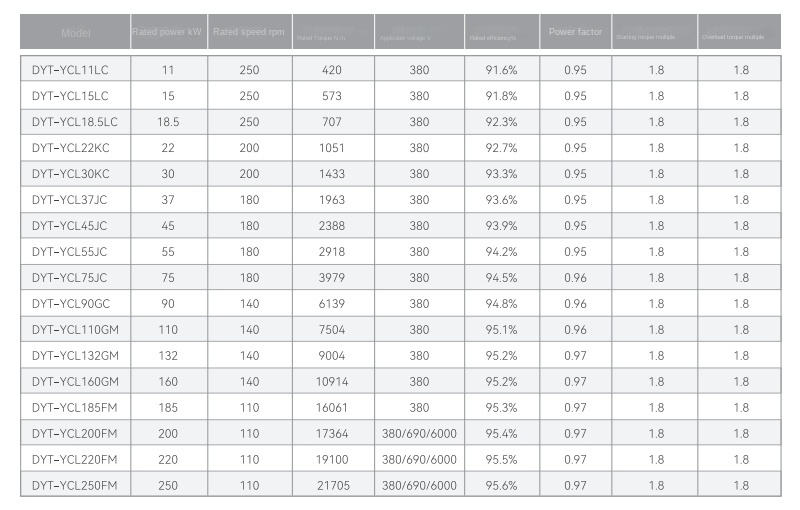

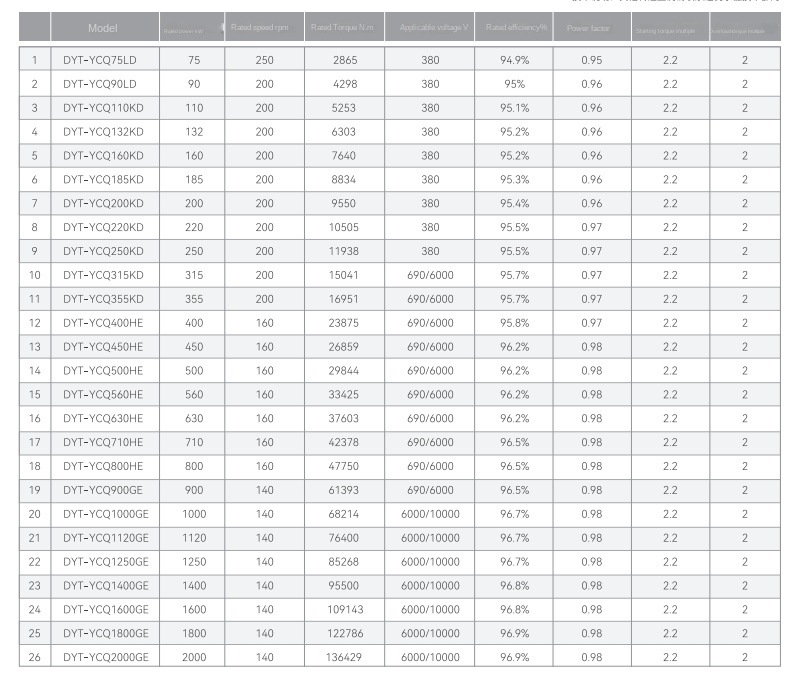

Special permanent magnet synchronous direct drive motor for ball mill-parameter table

Bucket elevator XD

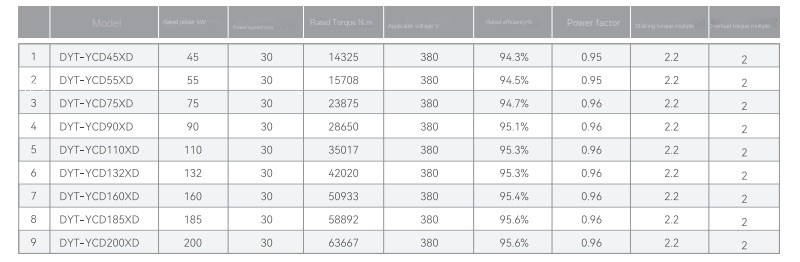

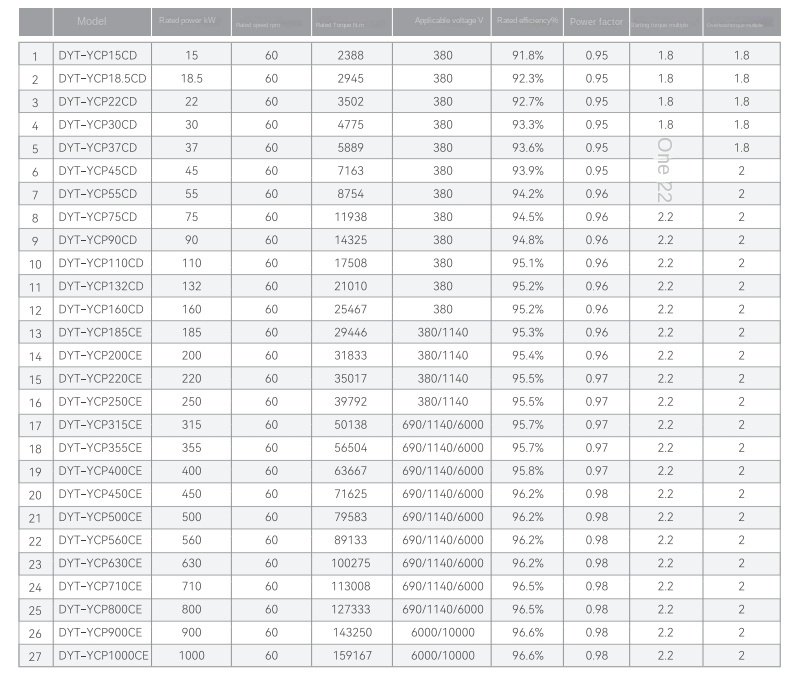

Bucket elevator XD series special permanent magnet synchronous direct drive motor-parameter table

Bucket elevator YD

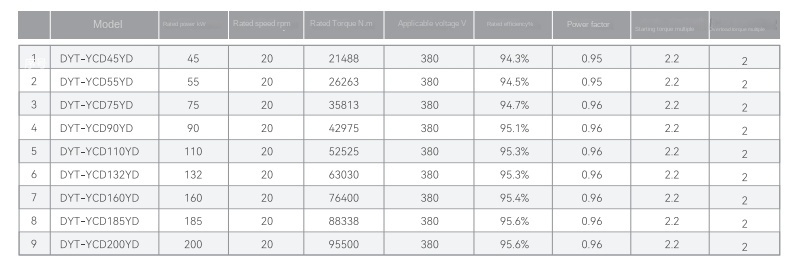

YD series special permanent magnet synchronous direct drive motor for bucket elevator-parameter table

Belt conveyor

Permanent magnet synchronous direct drive motor for belt conveyor-parameter table

Product Message

Get in touch with our team in a timely manner and be happy You offer help

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible